Fluorwhiter DT is used to dacron or T/C blend fabrics to produce fluorwhiter effect and used to dyeing.printing and painting in the processes.The goods can produce brightening colour and brilliance printed pattern.

Properties:

1. Fluorivhiter DT is an organic compound.

2. Properties as Uvitex ERN. Uvitex EHF etc.

3. Emulsifier of the oil-in-water type.

4. Emulsifier of the negative ionic type.

5. Violet Fluorescent colour cast.

6. Nor-ionic-type.

7. Stable chemical properties such as resistance to acid & alkali, etc.

finishing agents.

8. Be mixed by the negative or non-ionic surface active agents, dyeing, pigment, painting and resin

Be not mixed by the positive matter as indicated above.

9. Common uses : Steeping: 2-3% (OWF)Padding: 20-30g/L

10. Temperature and baking time: 160-190°C/3-5min.

11. Stable period of the emulsifier: a half year.

( if the emulsificr bad sedimentation and is separated in the solution, please use mixing method into

uniformily, than to use.)

Process:

Padding process:

1. T/C (65/35) blend fabrics technological processes:

Scaming --- Singeing-- Scouring --Bleaching-- Heat Setting -- Mercerizing -- Dacron fabrics

brightening-- Rebleaching -- Heat stenter - Cotton fabrics brighting - Finishing.

2. T/C (65/35) bleach fabrics pad-dyeing formula: Fluorwhiter DT 25g/L.

3. T/C (65/35) blend fabrics processing parameter and control:

Hot air dry temperature: 100-120°C.

Baking temperature : 160-165°C.

Baking time: 2.5 min.

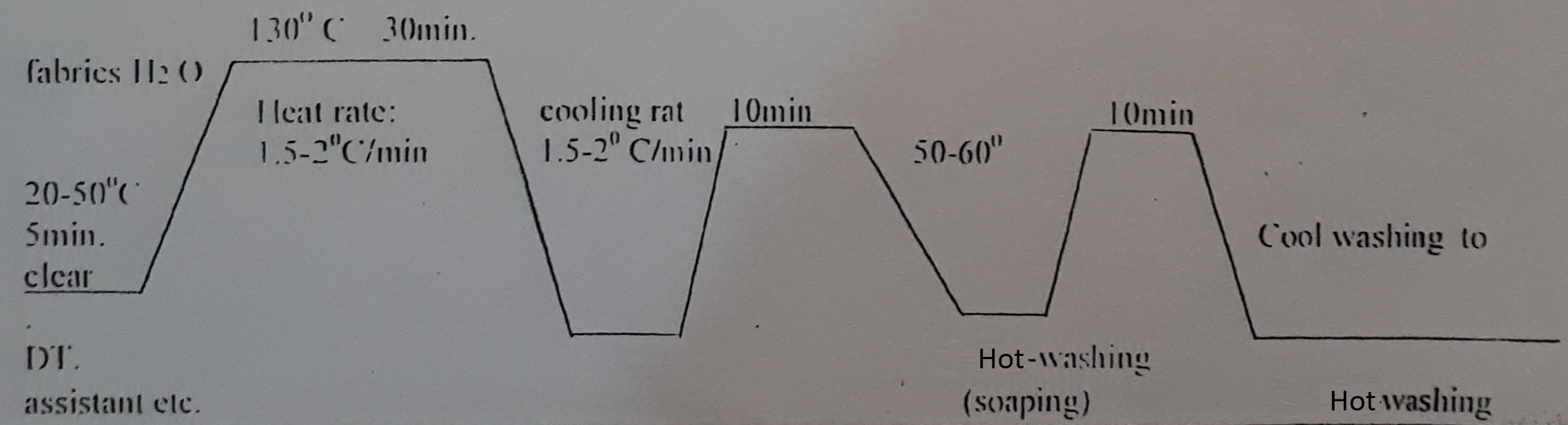

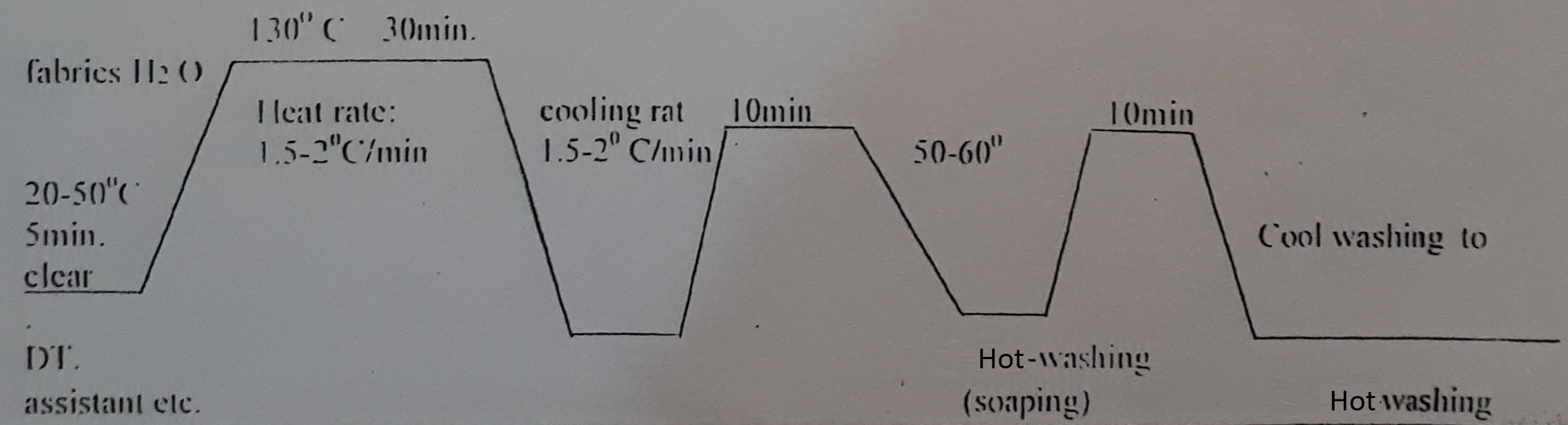

Steeping Process:

1. Dacron fabrics technological processes:

Steaming -- Scour-relaxation (washing) --lluorescent brightening --Heat-- washing (soaping) --Heat--

washing--cool-washing to clear- Heat stenter--finishing.

2. Dyeing formula: ( liquor ratio 1:18-20).

Fluorwhiter DT 2-3% (0.w.f.)

Non-ionic leveller 0.5ml/l.

CH3 COOH (98%) 0.5 ml/I. (pH= 5.5-6.5).

Dyeing program and control: