Product Profile

Specific alkali agent DA-010 an eco-friendly powder product, easy soluble in the water. In addition, it can be put not only in the dying machine but also in the dosing system.can substitute for soda ash, when failed in dying, you can add Specific alkali agent DA-010 into the same bath, without changing a new one. What's more,

1. It reduce the storage of soda ash.

2. It reduce the cost of dying.

3. It reduce the effects ratio.

4. Shorten the dying time and

5. Improves the dying quality.

In the process of using this product, PH value is stable. Retarding effect is better than soda ash, it has level effect on dying without colour difference. It also shortens the dying time. This product has an excellent effect on the colour of black and red.

Properties

* Component: Buffer oregano-inorganic compound

* Appearance: white powder/Granular

* ph value (1% solution): 12-13

* Solubility: Easily soluble in the cold water, after diluting with water to 1:(7-9) then use same

dosage with soda ash.

* Storage Stability: sensitivity to temperature below O"C

Characteristics

1. Especially suitable for reactive dyes dying of fibre. It can substitute for soda ash.

2. When it used in fibre, because the high dyestuff fixing so that it provides excellent rubbing fasincss. .

Not like NaOH as alkali agent it will not decrease the freshness, absorption efficiency, colour change. Furthermore, It also does not impart lot difference and colour

unstable phenomenon.

3. Used in various types of dying equipments, including dosing system, especially suitable for

low bath ratio cheese yarn dyeing. This new alkali agent is used, can keep the dyeing liquid in liquid condition, keep in best circulation, easily to get level dying effect, not like the soda ash,

increase the viscosity to cause the circulation worse down.

4. Excellent dying repeatability, and there is no dye lot difference.

5. Suitable for every type of reactive dyestuff, such as Lehcafix, Cibacron, Rehmazol, Sumifix.

procion, and so on. Not like soda ash, this alkali DA-010 can be added in dyeing bath at one

time, that can shorten a lot of dyeing time.

6. In the process of dying, PH is stable As to retarding effect, is better than soda ash, hence, can

obtain levelling dyeing.

7. Reduce the stock space in warehouse.

8. Especially suitable for those dyestuffs such as turkey blue, emerald green and brown, that easy

to cause dyeing defcat.

9. Easy to wash off, can save lot of water, Not form alkali speck (soda ash will form speck), and

not form lump in the bottom and in the pipe, that prevent second time staining,

10. Especially, excellent performance to black and red colours.

Application

1. Diluted with water to 1:17-9) before using, so that the dosage is equal to that of soda

ash. Never add the powder directly into the dying vat Mcs.

2. The dosage depends on the operation of dying system average dosage is about 1-4g/L.

Please confirm it in the laboratory first.

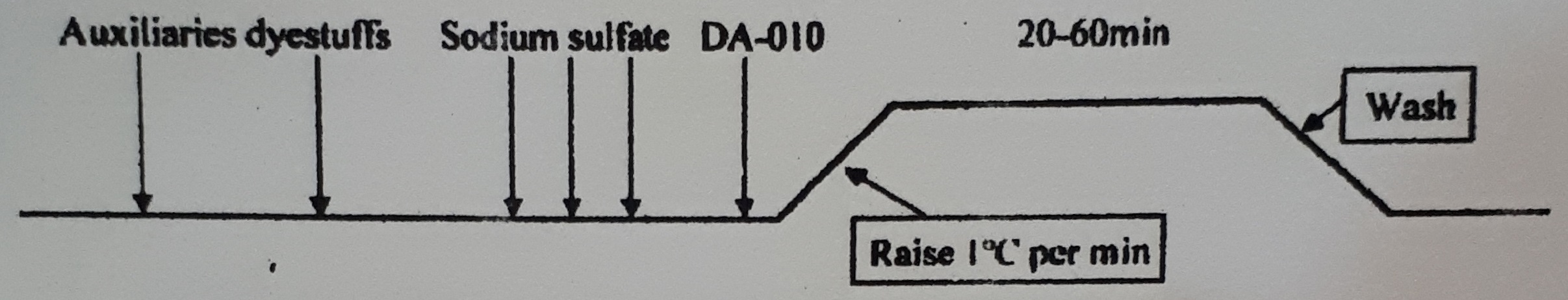

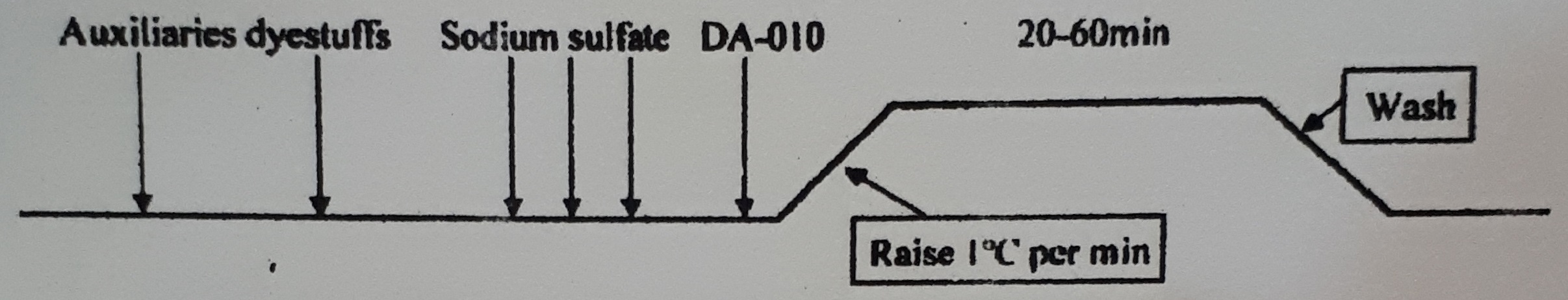

3. The procedure of dying is displayed as follows:

Attention

1. DA-010 is a kind strong alkali and corrosive agent, it should be handle in a secure

way, and keep it from skin and eyes, if stained, you should change it and spray the

water on quickly.

2. DA-010 can substitute for soda ash.

3. After dilution, it can be directly added into dying bath. Accordingly to our experience,

when it's used correctly, there is no change of colour shades, except for special

orange, red and green dyestuffs. Be sure to use dyestuffs reasonally.

4. DA-010 is used to dye middle and deep colors, if the color yield is too light, can add

more 8 to 12 g/L of Sodium Sulfate or keep the temperature longer for about 15-30 min. If you add lgl of Sodium Carbonate before adding the dyestuffs, it will solve the

problem basically.

5. DA-010 is more stable than the strong alkali like Sodium Carbonate or NaOH

6. Little deposit left in the bottom of package that will not affect the quality of product.

7. Close the drum cover to prevent it from expose to air.

Indication

As we can't fully take into account every condition the product is used in our customers has to apply their technique and products according to the corresponding conditions by trials. When mixing with other auxiliaries, you have to choosc suitable products and their proportions with experiments.

We guarantee the security, transportation, processing of products and support to our customers. If you need more information of our products. please contact our Technical Department.

Attention

1. DA-010 is a kind strong alkali and corrosive agent, it should be handle in a secure

way, and keep it from skin and eyes, if stained, you should change it and spray the

water on quickly.

2. DA-010 can substitute for soda ash.

3. After dilution, it can be directly added into dying bath. Accordingly to our experience,

when it's used correctly, there is no change of colour shades, except for special

orange, red and green dyestuffs. Be sure to use dyestuffs reasonally.

4. DA-010 is used to dye middle and deep colors, if the color yield is too light, can add

more 8 to 12 g/L of Sodium Sulfate or keep the temperature longer for about 15-30 min. If you add lgl of Sodium Carbonate before adding the dyestuffs, it will solve the

problem basically.

5. DA-010 is more stable than the strong alkali like Sodium Carbonate or NaOH

6. Little deposit left in the bottom of package that will not affect the quality of product.

7. Close the drum cover to prevent it from expose to air.

Indication

As we can't fully take into account every condition the product is used in our customers has to apply their technique and products according to the corresponding conditions by trials. When mixing with other auxiliaries, you have to choosc suitable products and their proportions with experiments.

We guarantee the security, transportation, processing of products and support to our customers. If you need more information of our products. please contact our Technical Department.

Attention

1. DA-010 is a kind strong alkali and corrosive agent, it should be handle in a secure

way, and keep it from skin and eyes, if stained, you should change it and spray the

water on quickly.

2. DA-010 can substitute for soda ash.

3. After dilution, it can be directly added into dying bath. Accordingly to our experience,

when it's used correctly, there is no change of colour shades, except for special

orange, red and green dyestuffs. Be sure to use dyestuffs reasonally.

4. DA-010 is used to dye middle and deep colors, if the color yield is too light, can add

more 8 to 12 g/L of Sodium Sulfate or keep the temperature longer for about 15-30 min. If you add lgl of Sodium Carbonate before adding the dyestuffs, it will solve the

problem basically.

5. DA-010 is more stable than the strong alkali like Sodium Carbonate or NaOH

6. Little deposit left in the bottom of package that will not affect the quality of product.

7. Close the drum cover to prevent it from expose to air.

Indication

As we can't fully take into account every condition the product is used in our customers has to apply their technique and products according to the corresponding conditions by trials. When mixing with other auxiliaries, you have to choosc suitable products and their proportions with experiments.

We guarantee the security, transportation, processing of products and support to our customers. If you need more information of our products. please contact our Technical Department.

Attention

1. DA-010 is a kind strong alkali and corrosive agent, it should be handle in a secure

way, and keep it from skin and eyes, if stained, you should change it and spray the

water on quickly.

2. DA-010 can substitute for soda ash.

3. After dilution, it can be directly added into dying bath. Accordingly to our experience,

when it's used correctly, there is no change of colour shades, except for special

orange, red and green dyestuffs. Be sure to use dyestuffs reasonally.

4. DA-010 is used to dye middle and deep colors, if the color yield is too light, can add

more 8 to 12 g/L of Sodium Sulfate or keep the temperature longer for about 15-30 min. If you add lgl of Sodium Carbonate before adding the dyestuffs, it will solve the

problem basically.

5. DA-010 is more stable than the strong alkali like Sodium Carbonate or NaOH

6. Little deposit left in the bottom of package that will not affect the quality of product.

7. Close the drum cover to prevent it from expose to air.

Indication

As we can't fully take into account every condition the product is used in our customers has to apply their technique and products according to the corresponding conditions by trials. When mixing with other auxiliaries, you have to choosc suitable products and their proportions with experiments.

We guarantee the security, transportation, processing of products and support to our customers. If you need more information of our products. please contact our Technical Department.